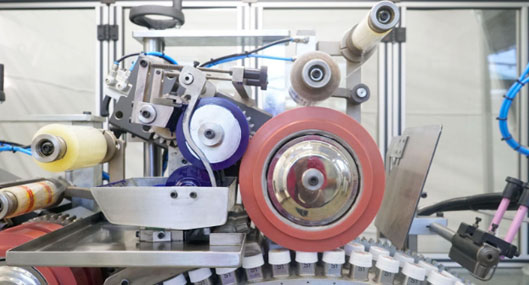

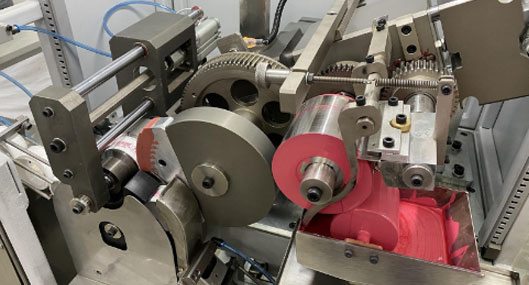

Rotary Pad

Silicon rollers are used in rotary pad printing to pick up the artwork from the cliche and transfer it to the substrate.

Quality

We use the best quality European silicon to mold our rotary pads. Therefore, the quality of material is consistent from batch to batch. Also it provides extended usable life and is less prone to swelling.

The cavities are precisely machined to get an extra smooth outer surface and geometric accuracy of the manufactured pad.

The cores for rotary pad printing are made of graded aluminum. Their machining quality is checked before molding.

Care is taken that there are no bubbles during molding. And that the silicon bonds strongly to the aluminum core.

Production

The shore hardness can be varied to suit the printing application. For rotary pad printing we vary the hardness between 28 and 50 shore.

We keep stock of aluminum cores, so that we can quickly dispatch upon receiving your order.

The pads are safely packed before dispatch.

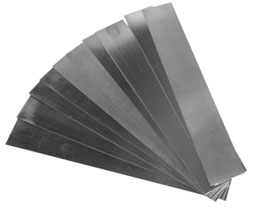

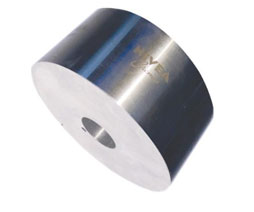

Cliche Roller

Cliche rollers carry the engraved image of the artwork for rotary pad printing. The applications include:

- Closures

- Bottles

- Face masks

- Pen barrels

- Pharmaceutical cartridges

- Cosmetic containers

- Teflon tape covers

- Sizers for clothes’ hangers

Artwork Processing

We have experience in processing artwork suitable for rotary pad printing applications. With knowledge of printing we are able to advise on achieving optimal printing quality through adaptation in the cliche.

Production

Our production makes about 20 cliche rollers per day. Normal lead time for processing cliche roller is 3 working days from artwork approval. In urgent cases, we may also be able to dispatch on the same day.

Popular standard roller sizes are:

- OD 100 mm x ID 25mm

- OD 60 mm x ID 25 mm

Width is decided as per printing machine.

In addition to these, we also provide special roller sizes upon request.

Quality Assurance

Our rollers are made of hardened tool steel with high dimensional accuracy and smooth surface free of defects. The rollers are inspected at every stage of manufacturing before and after engraving for quality assurance. The engraving depth is also a controlled parameter. The rollers are packaged properly in special corrugated boxes to avoid damage during transport.

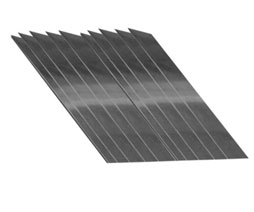

Doctor Blade

In rotary pad printing, the doctor blade removes the excess ink from the smooth non-engraved portions of cliche roller, such that the ink is only in the engraved areas.

We have a long lasting steel pad printing doctor blades. The blades are manufactured using high-grade quality of raw material and ground to precision.

Available in the following thickness:

- 0.3 mm

- 0.5 mm

- 0.8 mm

- 1 mm

Length and width can be customized to suit the printing machine.