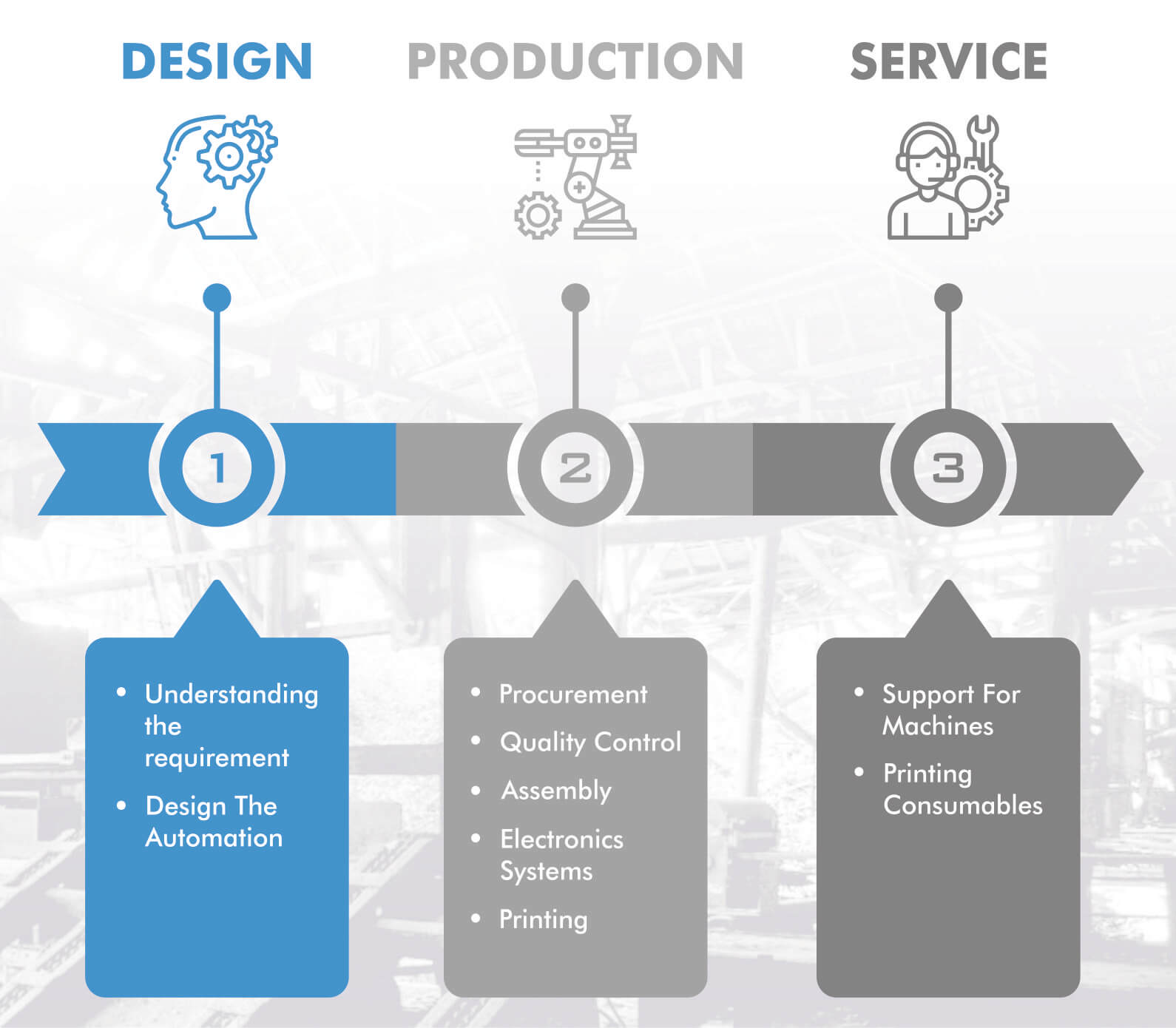

DESIGN

In Winner Screen we have highly skilled Design Engineers who are capable of undertaking challenging projects.

We make custom designed and built machinery to suit specific requirements. We work closely with clients to understand their expectations. We consider our Design team as our greatest asset.

Winner Screen has an in-house facility for design of machinery, components and new products on 3D CAD software. We engineer original innovative designs to solve customer’s printing problems. Talented technical staff trained by German engineers.

Our designers have a good in depth knowledge of graphic arts.

PRODUCTION

Winner Screen produces/manufactures its machines by using following elements —

- PROCUREMENT

- QUALITY CONTROL

- ASSEMBLY & TESTING IN HOUSE

Winner Screen processes are controlled and monitored by a customized ERP solution. We start production as soon as we get an indent from the sales department and then to keep planning. The production department maintains stock of frequently required material by our clients. We follow the Kaizen principle by continuous improvement in machine building which involves quality, efforts, Involvement of skilled and experienced employees and willingness to change. We have selective vendors who are proven and reliable in providing the material and expertise.

PROCUREMENT/PURCHASE

Winner Screen acquires raw materials, parts and bought out from external sources as well as we do in house manufacturing process. For any indent/requisition our purchase team takes a minimum 3 comparisons from the vendors and finalizes competitively. We process purchase orders with machines scheduled. We maintain the GRN system and inventory control.

QUALITY CONTROL

Quality control starts right from raw material selection and inspection. An incoming inspection department checks the various parameters of parts procured from quality vendors to ensure smooth manufacturing. During assembly or trials of machinery if there is any modification required, high precision in-house CNC machines are used to meet the customer’s high expectations.

Benefits of using quality control–

◊ Increase customer loyalty

◊ Gain repeat business

◊ Reduce liability

◊ Improve safety

ASSEMBLY

Winner Screen Machines are always assembled inside the premises by expert technicians. After the assembly of each machine, it is tested by the in-house engineers prior to customer attendance.

This ensures smooth and correct operation of machines at customer sites when put in production. Winner Screen also provides basic training the handling of the machine and since the same technicians who assemble the machine are on site for installation, there is total reliability of the service provided by us.

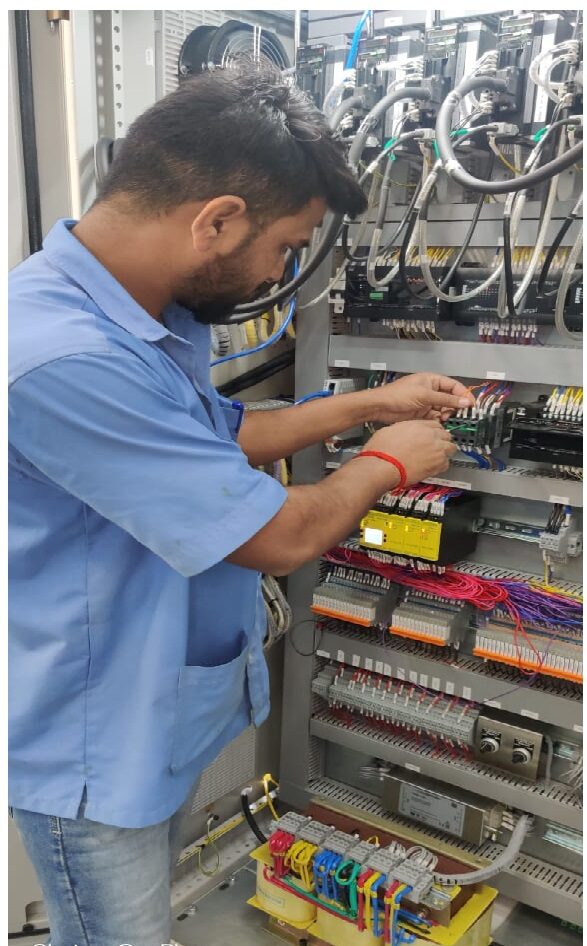

ELECTRICAL SYSTEMS AND SOFTWARE

Winner Screen Machines has in-house design of electrical systems for machines made by the company. The control panel and field devices of the system are wired and assembled in the premises. Winner Screen Machines also undertakes the programming of PLC’s and other operator interface systems, working in synergy with the suppliers of automation products.

Winner Screen machines are also enabled with an Ethernet facility which ensures remote access to the PLC. This ensures quick and timely support to the machine software if required.

SERVICE

“YOUR PRODUCTION IS OUR PRIORITY”

With more than 30 years of expertise in the printing industry, Winner Screen has one of the most experienced team of engineers, technicians and printers to attend your technical queries.

Since Winner Screen believes in ‘Employee First’ policy, we have been able to retain and are proud to be associated with our employees some of whom have been working with us from last 20 years.

Our team are specially trained to support client with a view to ensures the system are running round the clock with least downtime possible, so that you may be able to get maximum out of our precision engineered, high performance machine.

Our Service and Spare Part departments are ready to assist you at any time and can be contacted by email or phone.

SPARE PARTS

Winner Screen maintains a large spare parts inventory, and we also maintain the engineering drawings of every printing systems we have ever built. The key to our system is machine serial number which can be found on the identification plate affixed to the machine. This allows us to identify exact machine and the components that were fitted in it. We will have the drawings of the system and all of the parts that were incorporated in it. If we don’t actually have a part in inventory, we can manufacture it within specified time period.

Keeping your priority in mind, we would always like to ensure that our customer’s business is not hampered for lack of spares.

Therefore, several of the spare parts of our machines are readily available with us, these include:

◊ Mechanical spares of our machines

◊ Pneumatic components

◊ Electrical and Electronic components

All of our spares can be procured at an affordable cost, as we believe in sustainability of our business as well as the clients we deal with.

We request our customers to use original spare parts to maintain long life of our machines.