Murakami – Screen making chemicals

Murakami product line is designed to provide consistent and high quality non-stop print production using the finest emulsion and all prepress chemicals.

Murakami invented to SBQ pure photo polymer technology resulting in faster exposure time and exceptional stencil resolution and durability

Murakami dual cure emulsions offer wide exposure latitude and greater stencil flexibility.

We have following types of Emulsions:

Photocure SR Emulsion:

- Pre-sensitized emulsion, ready to use. No diazo required

- User friendly thanks to wider exposure latitude

- High resolution emulsion for reproduction of detailed and fine images

- Long shelf life

- Suitable for PCB, plastic, paper printing applications

- Suitable for solvent based inks and UV links

Advance 20:

- Fast exposure premium dual cure type emulsion

- Excellent durability, superior solvent resistance

- Easy to reclaim, extended re-use of screen

- Superior resolution, sharp image definition for finest image reproduction

- Suitable for fine line graphic image, PCB patterns, nameplate and ceramic tiles

- Suitable for solvent based inks and UV inks

Frame Adhesive G 18:

This is used for adhesion of screen cloth on aluminium frame

- Fast drying and simple to use

- Excellent adhesive characteristics and heat resistant

- Easy to remove when reclaiming

TXR Emulsion:

- Pre-sensitized emulsion, ready to use. No diazo required

- Wider exposure latitude

- High resolution emulsion for reproduction of detailed and fine images

- easy to build EOM by fewer coats

- Best suited for textile and flag printing with plastisol and water based inks

- Consistent emulsion profile over the mesh, lower Rz value

- Extended shelf life

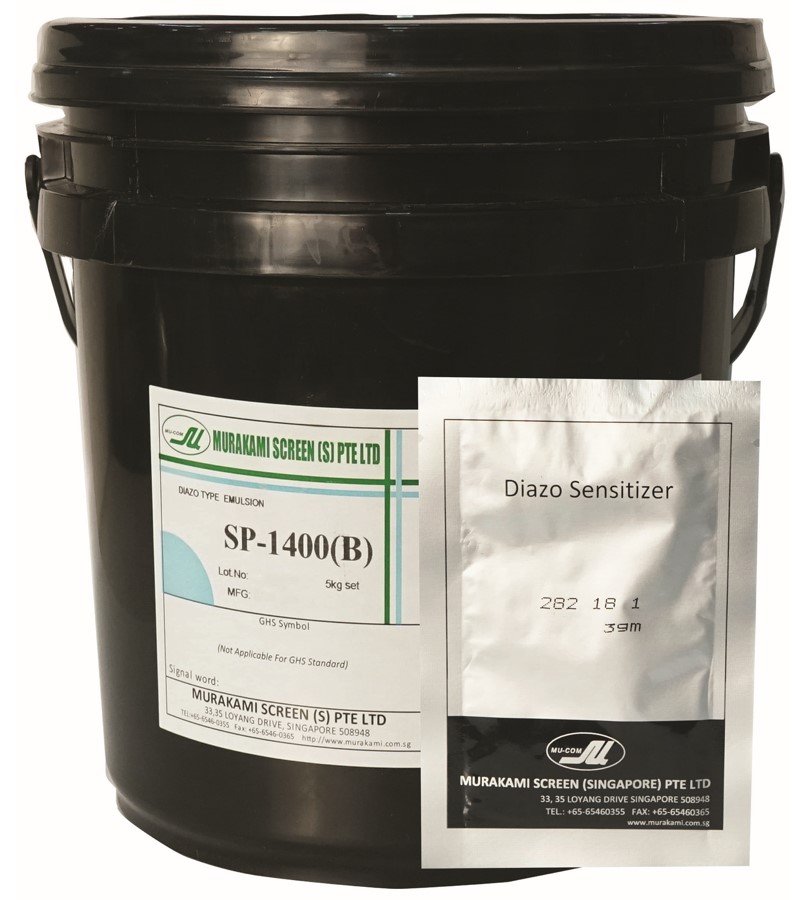

SP- 1400

- Universal type water resistant emulsion

- Textiles, banners, T-shirt, towels and water based inks

- Recommended for water bome paste used for electronic devices

- Faster exposure than normal diazo type emulsion. Water exposure latitude

- Easy to reclaim, extended re-use of screen mesh

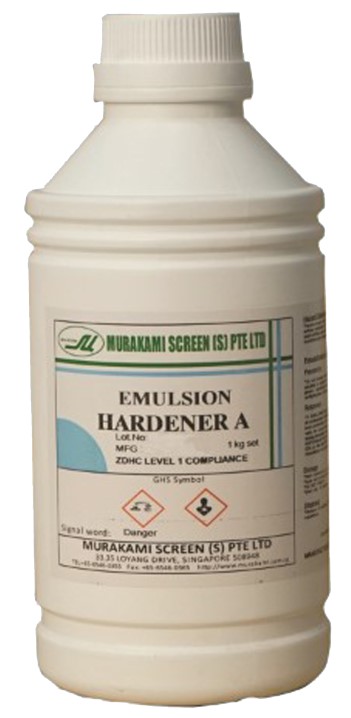

Harderner A & DL

- Raised water resistance of stencils to any type of emulsion

- Increase durability to stencils for printing with solvent based inks for printing in high humidity conditions

- Whereas it does not have intense smell and a stimulus against your eyes often found in conventional hardener, it is still to achieve same results as conventional one

- It does not contain heavy metals