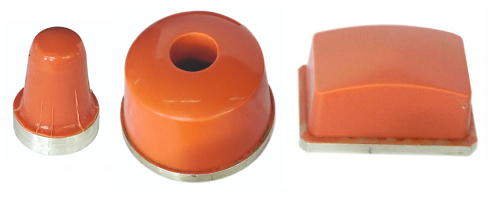

Printing Pad

A pad printing pad is the ink transfer mechanism in a pad printing machine, the pad picks up the ink (image) and transfers it to the product. A pad is a three-dimensional object molded of silicone rubber. Pad printing pads vary in shape and diameter depending on the application. It is very important to choose the right pad printing pad and use it in the right way so a good print quality can be achieved. The type of silicone and hardness of the pad printing pad depends upon the application.

Our Silicon pads are available in three different Hardness of pad namely soft, medium and hard

We have various type of pads:

- Round pads

- Rectangular pads

- Square pads

- Special pads for specific requirements can be developed and manufactured on request.

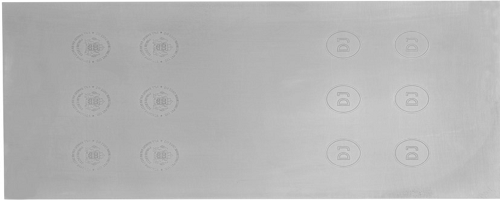

Cliche Plates

We have in-house facilities to prepare customized printing plates. Our cliche plate is made of stainless steel and OHNS and maintains a proper surface for accurate printing. Our process on cliche roller is chemical etching.

This cliche roller and plate is suited to various applications such as Automotive, Bottle caps, Promotional items, Glass perfume bottles, Medical technologies, Watch dials house, Household appliances, Decals, Toy Industries. We have experience in processing artwork suitable for rotary pad printing applications.

Our production makes about 20 cliche plates per day. Normal lead time for processing cliche roller is 3 working days from artwork approval. In urgent cases, we may also be able to dispatch on the same day.

Popular standard roller sizes are:

- 295 x 148 x 11.5mm

- 320 x 145 x 11.5 mm

- 250 x 100 x 10mm

- 215 x 100 x 10 mm

In addition to these, we also provide special roller sizes on request.

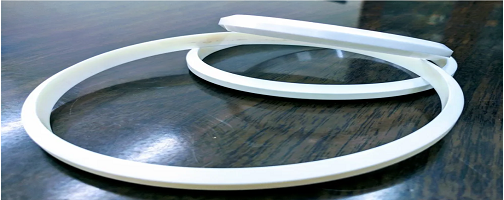

Ceramic Ring

Pad printer with sealed ink cup system is characterized as ink saving, odourless and non-pollution. It’s satisfied with requirements of environmental protection.

Pad printing machines uses closed ink cups with ceramic scraping rings for the inking of the clichés.

Ceramic Ring Internal Diameter: 90mm, 110mm and 130mm

Make: Italian

FEATURES:

- High temperature resistance

- Corrosion Resistance

- Abrasion resistance

- Good seal ability

- High Hardness

- High mechanical strength

- High bending strength

- Long application life

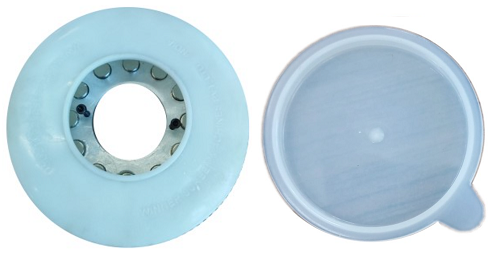

Ink Cup

Ink Cups are used to store the ink and to wipe the cliche plates. We developed the magnetic ink cups which results in a neat and clean operation. The cups are fitted with stronger magnets for sealing and wiping the cliché plate with ink inside the cup. With the sealed ink cup systems, much less ink is used and the solvent does not vaporize easily resulting in cutting of printing cost. The sealed ink cup systems are safe and environment friendly.